In all walks of life, the safety of wires and cables is crucial. Especially in high-temperature environments or places with fire risks, effective heat protection solutions are needed to protect wires and cables from heat and fire damage.

1. Pyrojacket casing overview

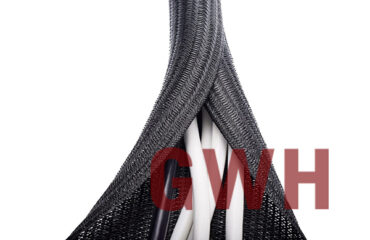

Pyrojacket casing is an advanced heat source protection material woven from high-temperature nanofibers. It is able to withstand extreme temperatures in hot environments and provides excellent protection. Pyrojacket sleeves are manufactured using special nanotechnology, giving them excellent thermal resistance and wear resistance.

2. Key Features and Benefits

2.1 Strong thermal resistance: Pyrojacket casing can withstand heat sources in high temperature environments, effectively preventing fire and thermal damage.

2.2 Fire resistance: The burning risk of wires and cables in high-temperature environments is a serious problem. Pyrojacket casing has good fire resistance, which can prevent the spread of flames and reduce fire risks.

2.3 Wear resistance: Pyrojacket casing has excellent wear resistance, which can prevent wires and cables from being easily damaged by heat sources due to wear.

2.4 Flexibility and easy installation: Pyrojacket casing adopts braided structure, which has good flexibility and is easy to install and adjust.

3. Application areas

Pyrojacket casings are widely used in many fields, including but not limited to the following:

3.1 Petroleum and chemical industry: In high-temperature environments such as oil drilling and chemical plants, Pyrojacket casing can protect wires and cables from damage by heat sources and chemical substances.

3.2 Automotive and aviation fields: In high-temperature engines and exhaust systems, Pyrojacket sleeves can provide protection and ensure the normal operation of wires and cables.

3.3 Electric power industry: In places such as thermal power plants and substations, Pyrojacket bushings can protect power transmission lines from high temperatures and fire threats.