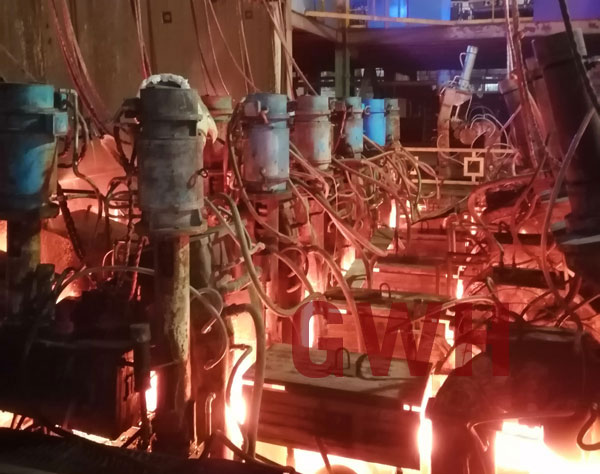

The high-temperature fire resistant sleeve is made of high-quality alkali-free glass fiber yarn braided into a tube, coated with organic high-temperature resistant silicone resin after high-temperature treatment. High temperature resistant bushing with flame retardant, heat insulation, thermal insulation, resistance to electricity, soft and so on. High-temperature resistant bushing is mainly used in steel plants, smelters, glass plants, fire-fighting equipment, large-scale transformer and other high-temperature places of cable insulation protection.

High temperature protective casing is widely used in high temperature area of electric power, chemical industry, metallurgy, shipbuilding, machinery manufacturing and other industries Heating area cable, fluid pipeline, Feed Quick Change Joint, Rolling Area Roller Table, rolling mill cable, oil pipe, sawing peripheral cable, oil pipe and joint, ladle car cable covering and so on. Performance test of high temperature fire resistant casing:

HIGH-TEMPERATURE ZIGZAG TEST:

After heating in a 260 ° c constant temperature furnace for 48 hours, there is no surface aging, cracking or peeling of the coating

Low temperature flexing test

After heating in a constant temperature furnace of -70 ° C for 1 hour, the surface did not break or the coating layer did not peel off.

Coating test:

After the constant temperature furnace continuous use test, no surface loss or dissolution phenomenon.

Combustion test:

Non-self-quenching and non-self-ignition (in accordance with UL“VW-1” and CSA“HFS” test)

TEMPERATURE RESISTANCE TEST:

(2000HR)260 ° c heating test, normal without abnormal

(30 SEC)1200 ° C heating test, glass fiber intact

Flame Retardancy Test:

Burning rate not less than 45s/25mm-SRG-1-7kv SRG-1-4kv, (motor insulation grade can reach C grade higher than h)

Normal low insulation failure voltage 7.0 Kv/min 4.0 kv/min

Normal average insulation failure voltage 10.0 Kv/min 7.0 kv/min